|

Product Description |

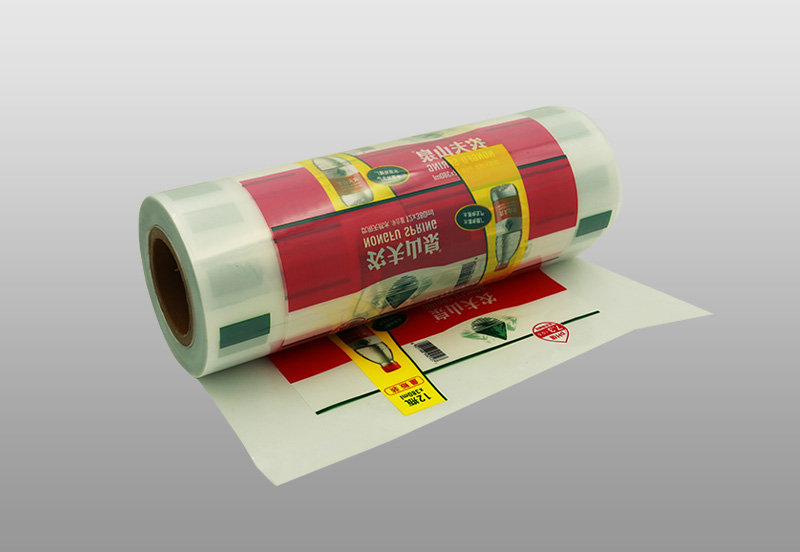

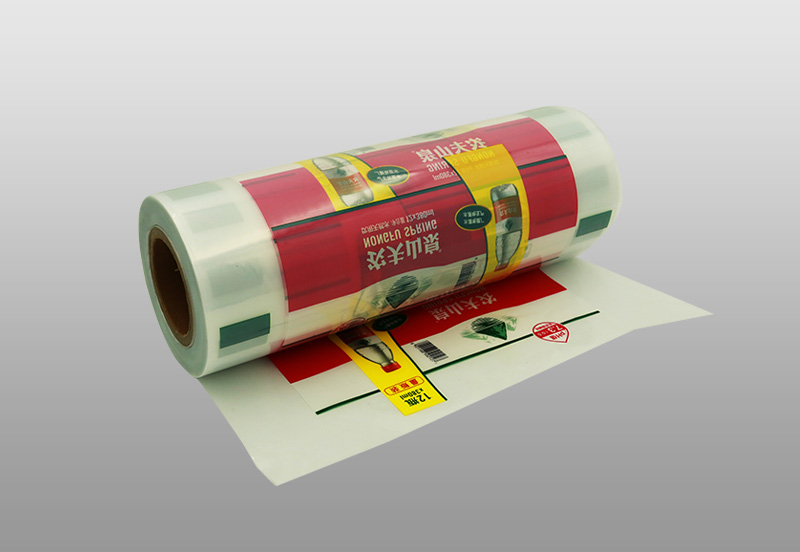

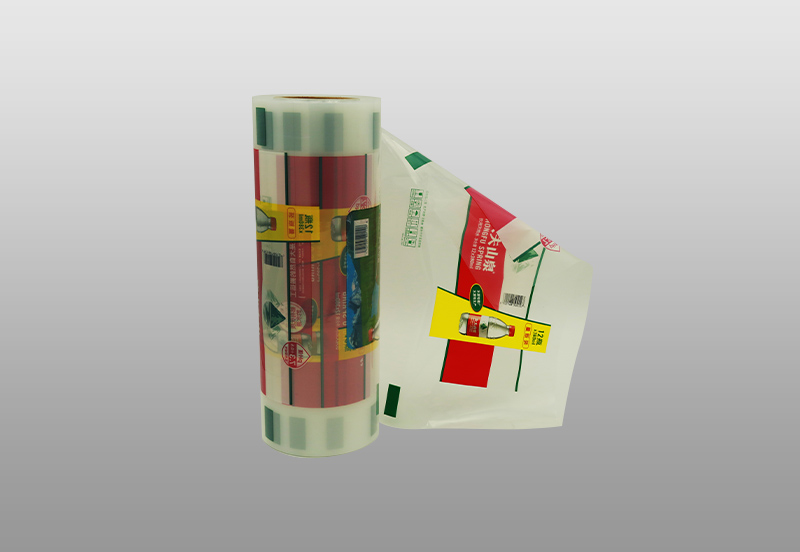

This product is a general-type heat shrinkable film, which made of polyethylene (PE) as the main raw material and a three layer coextrusion blow film. |

|||||||||||||||||||||

|

Product Features |

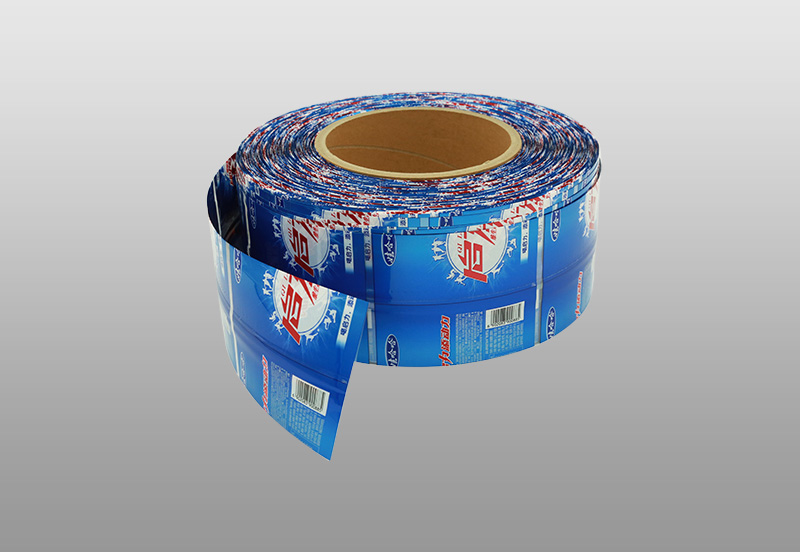

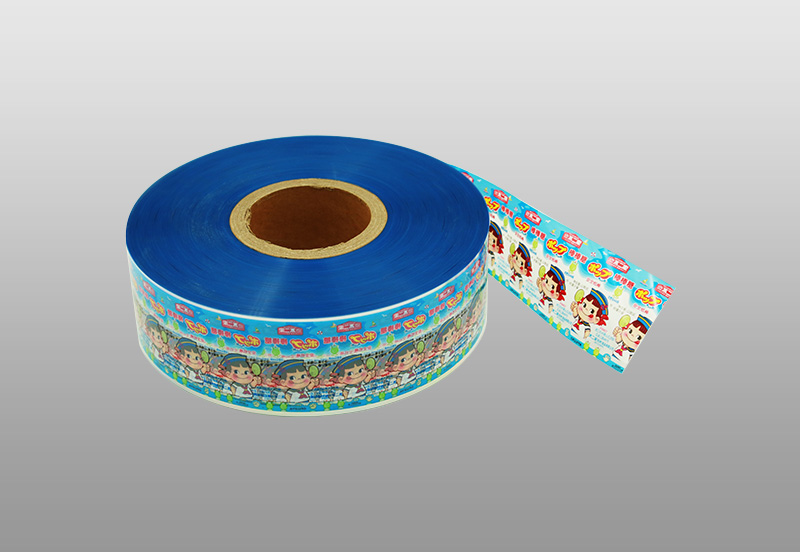

The product is widely used and is suitable for the cluster packing of food, beverage, daily necessities and so on. It has good shrinkage performance and excellent wrapping performance. With high tensile strength and toughness, it can meet the cluster packing of heavy products. With good printing adaptability to achieve good display effect. It has good wear resistance and can effectively protect the content. It is flexible in size to meet the requirements of different customers. |

|||||||||||||||||||||

|

Technical Indexes |

The data in the above table are for reference only, not the specification of the product. Film Thickness 60um |

|||||||||||||||||||||

|

Usage Method |

It is suggested that the drying path is longer than 150cm, three sections are heated, the temperature is 160-190℃, and the shrinkage process is about 10s. It is suggested that the conveyor belt is reticular or crawler type to avoid the use of roller type. The cooling must be sufficient. After the drying road, more than three large power fans should be equipped with cooling. The connecting place of the conveyor belt and the transport line are as smooth as possible, and the height difference is not more than 2mm, avoiding the sloshing of the products to cause the loosening of the packing.

After the packaging film is sliced by the automatic packaging machine, the single film package should be as compact as possible. When the product passes through the oven, and before the shrinkage is not fully cooled, the sloshing package is avoided. The products with good shrinkage have to be stacked after complete cooling to avoid loosening. Due to the differences in the processing equipment and processing technology of different manufacturers, it is suggested that the machine test be carried out first. |

|||||||||||||||||||||

|

Purpose |

It is suitable for the light mass packing of food, beverage, daily necessities and so on. |

|||||||||||||||||||||

|

Matters Needing Attention |

When loading the car, be careful to light and prevent the mechanical collision. When stopping in the middle of the road, it is not allowed to stop in the sun and prevent insolation. It should be stopped in the cool place and the unloading should be in the cool place, so as to avoid the shrinkage and deformation of the products. Storage conditions should be placed at a temperature of not more than 35 degrees. In a clean, dry, ventilated and cool storehouse, it should be stacked properly. The distance from the heat source is greater than 2m. When used, it should be used now and should not be placed in a high temperature workshop for a long time. Storage time: it is not suitable for more than half a year from the date of production. |

|||||||||||||||||||||

English

English Español

Español русский

русский 简体中文

简体中文