|

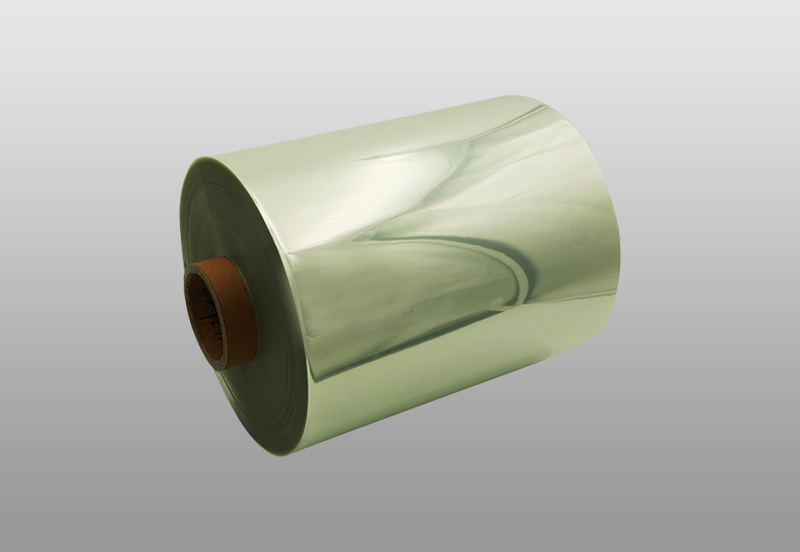

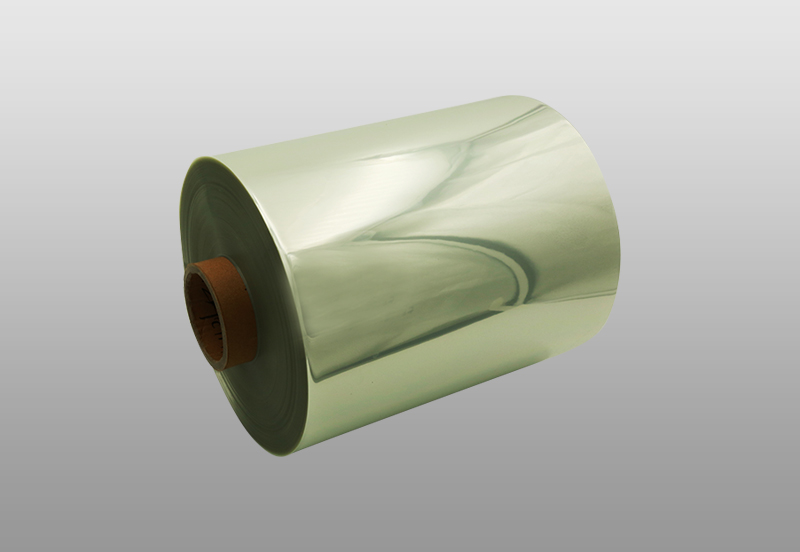

Product Description |

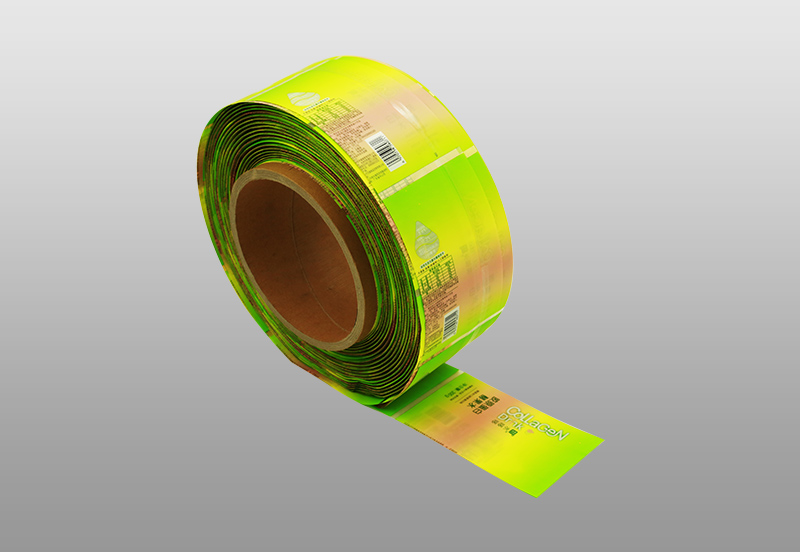

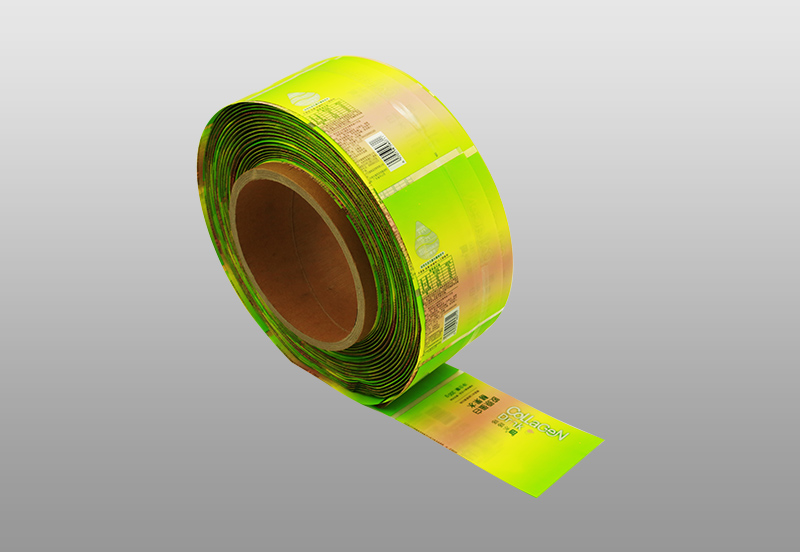

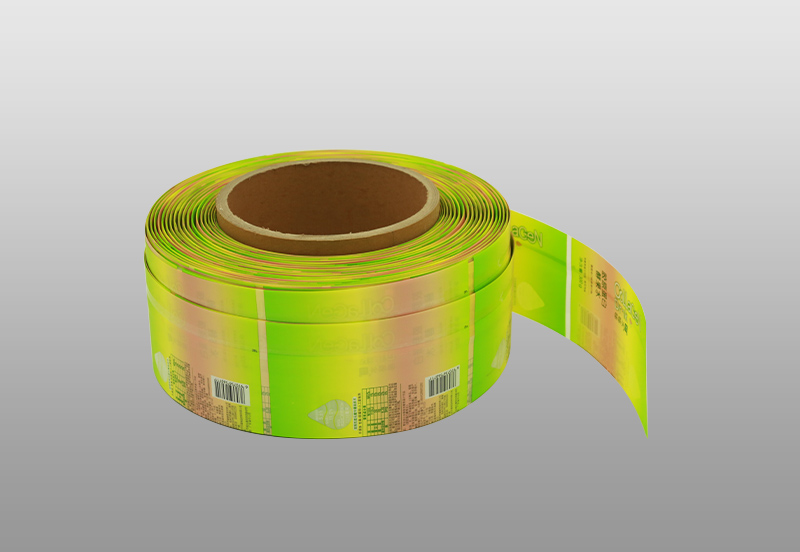

This product is made from modified polyester (PETG) heat shrinkable film as raw material, after printing, slitting, processing. |

||||||||||||

|

Product Features |

It is widely used in packaging of commodity containers, especially for the packaging of individual containers. Shrinkage rate is high, low temperature shrinkage and the use of a wide range of shrinkage speed. A graphic display of excellent performance, high light, matte, pearl, metal texture can be freely combined, in order to achieve the best visual effect of goods. It has good wear resistance and can effectively protect the commodity container. It can be water-proof, moisture-proof, and long period of use of graphic information. The processing and using are convenient, clean, and low energy consumption. |

||||||||||||

|

Technical Indexes |

Packing Speed: Depending on the size of the sleeve, the size of the length, the different equipment of the sleeve. Typical Sleeve Specification: The recommended length, folding width are my company in a number of large customers, empirical data by linear guide column sleeves of long-term using and accumulation, the actual use of products due to different sets of standard equipment, sleeve graphic design differences, bottle sleeves difficulty and other factors. It is recommended the length and diameter of folding for reference. |

||||||||||||

|

Usage Method |

This product is suitable for straight guide column type (Jin Huang KSL-2000, Pei Xin DSL-345MH, Li Feng AP-600), rotary type (Japanese automatic machine SL-720), rotary or rotary type sets of standard equipment. Generally used in a straight line guide set, the speed of packaging can be approximately 300-500 bottles of /min. The heat shrinkage heating way can adopt steam drying way, infrared ray, hot air and so on. In order to ensure a high shrinkage speed, it is recommended to use two steam drying tunnels with a total length of about 4m, the steam pressure is about 0.3MPa, and then shrink molding. The sleeve can be treated in different forms of exhaust holes and tearing lines on the basis of the actual use of the customer. |

||||||||||||

|

Purpose |

Used in beverage, wine, food, daily necessities (such as cosmetics, shampoo) and other commodity packaging. |

||||||||||||

|

Matters Needing Attention |

Because this product is heat sensitive products, heat shrinkage deformation, should be placed in 25 degrees below a cool, ventilated warehouse. The shelf life of the product is three months (storage temperature should be less than 25 ℃). Because the temperature in the workshop is generally high, especially in summer, it is recommended that customers not place excess volumes in the production workshop, and try to get as much as they can. |

English

English Español

Español русский

русский 简体中文

简体中文