Various industries are using high barrier film packaging as it preserves product quality and keeps it fresh. Some of the most common applications for this type of packaging are in the food, pharmaceutical and cosmetic industries. In addition to these industries, high barrier film packaging is also used in the construction and textile industries. The high barrier film packaging market is expected to grow at a steady CAGR during the forecast period. The market is projected to reach USD 16,884.8 million by 2022. Among all geographic regions, Asia Pacific is expected to witness the fastest growth in the market.

The high barrier film packaging market in Asia Pacific is expected to witness a high CAGR over the forecast period. The demand for packaged food in the region is expected to grow owing to rising consumer preference for processed food. Moreover, changing lifestyles of consumers in the region is also driving the demand for packaged food. Moreover, increasing purchasing power of consumers is also driving the demand for beverages. This trend is expected to further drive the growth of the global high barrier film packaging market in the coming years.

Therefore, manufacturers in this industry are striving to provide sustainable and environmentally friendly high-barrier film packaging. In addition to this, some manufacturers are also working on developing biodegradable barrier films.

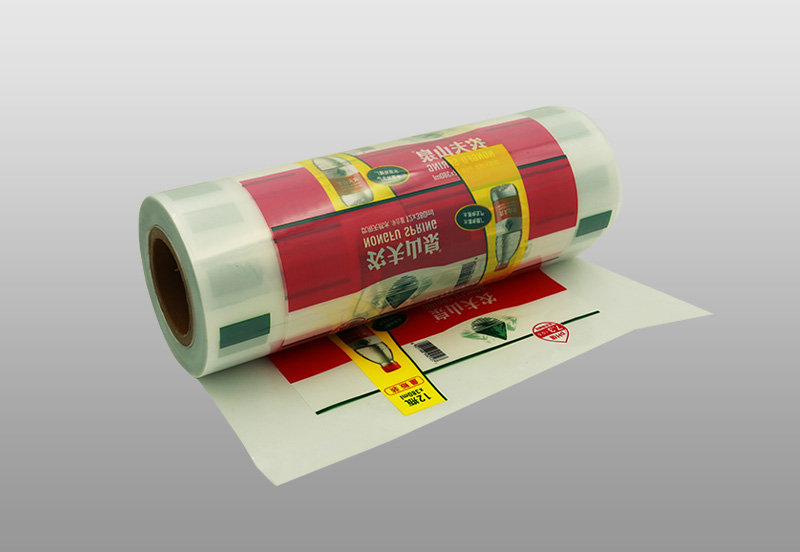

Manufactured using natural materials, these films provide a barrier to a variety of products. These films are also designed to provide safety and performance. These films are also designed to preserve the aroma and freshness of food products. They also provide protection from oxygen and other pollutants. They are used to package a variety of products such as cereals, ice cream, dried fruit, pickles, cereals, frozen foods and beverages. These films also provide a strong moisture barrier and thermal tack.

These movies also come in different formats. For example, non-rigid versions of films can be used to package solids. Static dissipative cleanroom versions of the film are also available to preserve product freshness. Also, the flex/flex format of film is becoming more and more popular. That's because the format helps with portion control. The flexible/flexible format of the film is ideal for retort ready-to-eat food packaging.

English

English Español

Español русский

русский 简体中文

简体中文