Plastic packaging bags are a common type of packaging in our daily lives. When we walked into a supermarket, almost all the oil, salt, soy sauce, vinegar, snacks and beverages, and beauty cosmetics on the shelves were packed in plastic bags.

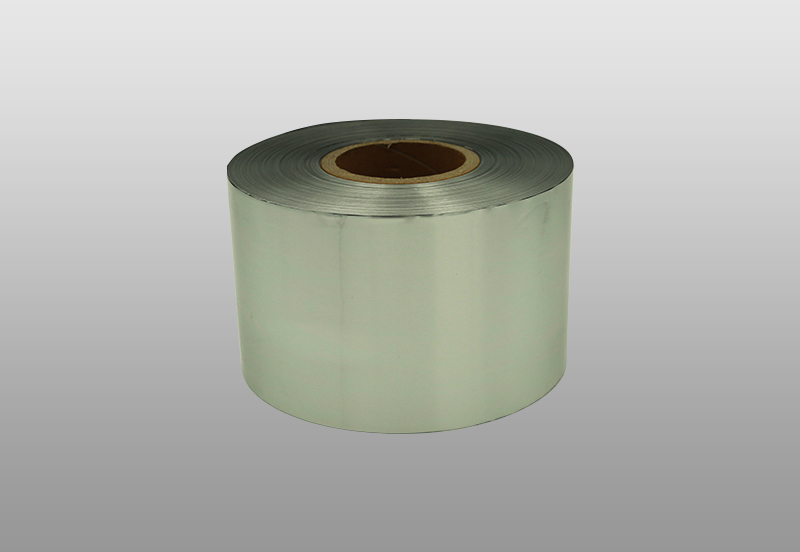

As the outer shell of the product, packaging also has its own unique requirements, especially in the food field. For example, flexible packaging must have gas and moisture barrier properties to ensure that its contents will not deteriorate. It must have good stretchability to ensure that it can withstand extrusion during transportation; the heat sealing performance must be good enough. Plastic packaging bags have good ink properties, and there will be no ink shedding and beading.

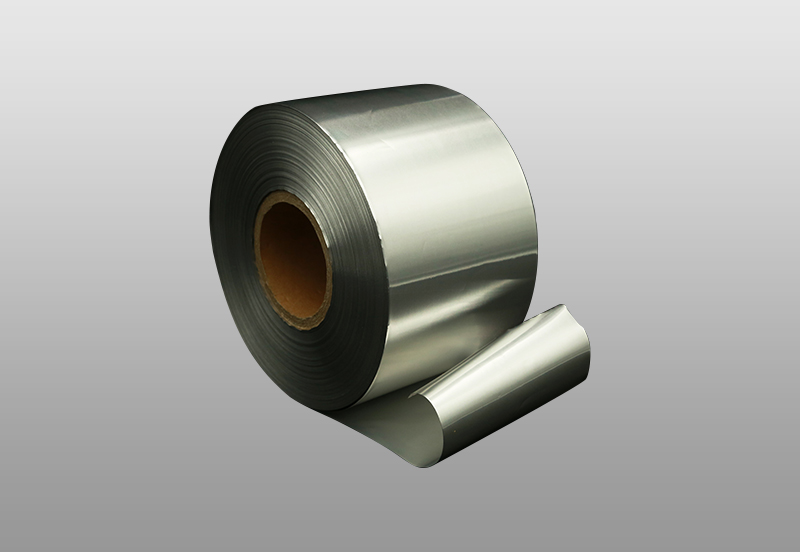

In recent years, with the deepening of the concept of environmental protection and the efforts of enterprises to reduce costs and improve production efficiency, plastic packaging bags are no longer limited to providing physical protection for the contents. It also needs to meet the new demands of the modern packaging industry. At present, plastic packaging bags are moving towards softer, lighter and thinner trends.

Unlike solid and non-deformable packaging materials such as glass, metal, and rigid plastic packaging, today's plastic packaging bags are developing in the direction of softness and light weight. Flexible packaging has many advantages, such as softness, small size and portability, which can better save raw materials and transportation costs.

Although it is called flexible packaging technology, plastic packaging bags can stand stably and ensure excellent storage performance, whether it is placed upright or on the side. Plastic packaging bags can also provide stronger toughness, friction resistance, heat sealability, balanced shrinkage and good optical properties.

For processors, the high melt strength of these polymers allows them to have higher bubble stability and higher yields. In addition, the melt strength and toughness of plastic packaging bags can reduce film thickness while maintaining high performance. Give manufacturers quality and cost advantages, and save raw materials.

English

English Español

Español русский

русский 简体中文

简体中文