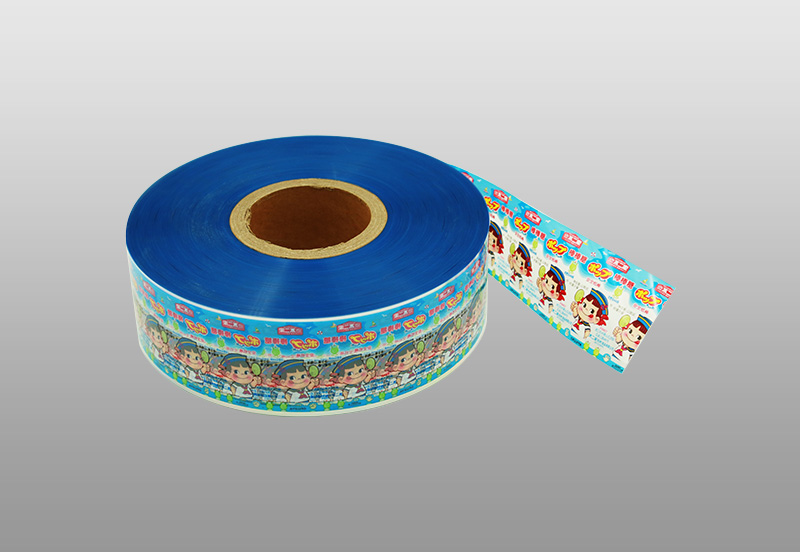

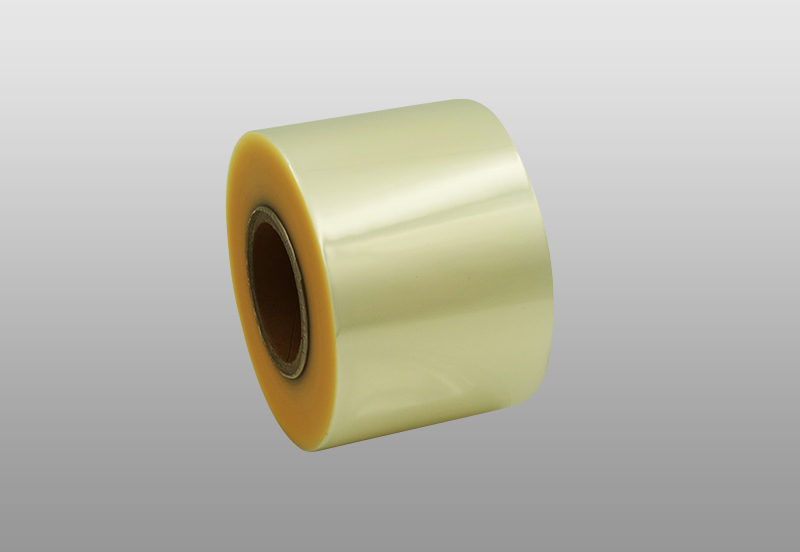

PP refers to plastic polypropylene, where C refers to the processing technology, which is a polypropylene (PP) film produced by a cast extrusion process. Among them, the high temperature cooking CPP film is also called RCPP film. This type of film has the properties of light weight, high transparency, strong mechanical adaptability, good moisture resistance and heat resistance.

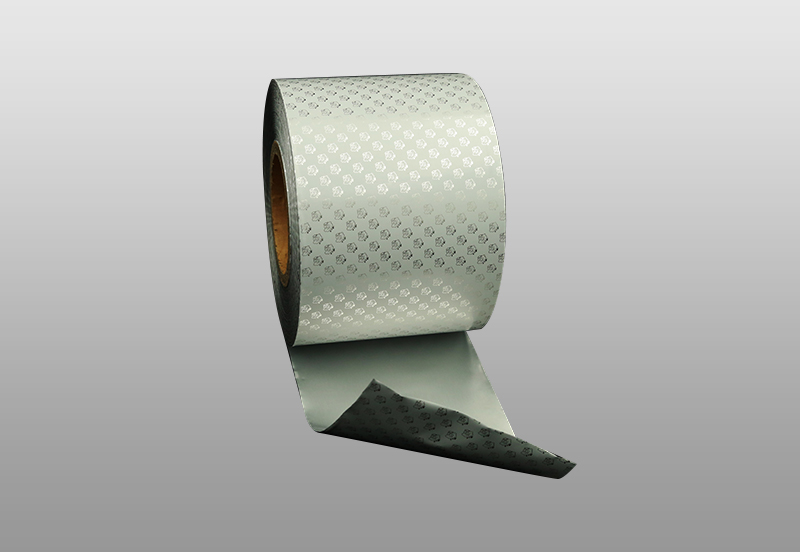

The RCPP high temperature cooking film and the aluminum foil material composite bag can achieve the best high temperature resistance effect.

Aluminum foil has good sealing properties and strong barrier properties. Aluminum foil has fewer pinholes.

The choice of aluminum foil material must ensure food hygiene and safety level, and its surface cleanliness must be high, without oil stains and floating dust, and its surface support must be high. A simple method is to check with pure water, which should flow on the surface of the aluminum foil. Oil stains on the surface of aluminum foil are not optimistic, which will harm the composite color fastness of aluminum foil and other raw materials, especially after the packaging bag is cooked at high temperature, delamination will occur.

Therefore, the RCPP high temperature cooking film using aluminum foil composite bag packaging bag has the functions of sealing, high fragrance retention, conditioner oil, and high temperature resistance.

English

English Español

Español русский

русский 简体中文

简体中文