1. Delamination caused by materials

Because aluminum foil bags are also multi-layer materials, in the process of selecting composite materials, different materials have different characteristics. If the packaging is different, it may be due to material errors and delamination will occur. For example, some products are rich in grease, some require high temperature processing, and some require low temperature storage. So I am buying aluminum foil bag composite packaging. When you pack it, you must tell the manufacturer that it is used for packaging.

Because aluminum foil bags are also multi-layer materials, in the process of selecting composite materials, different materials have different characteristics. If the packaging is different, it may be due to material errors and delamination will occur. For example, some products are rich in grease, some require high temperature processing, and some require low temperature storage. So I am buying aluminum foil bag composite packaging. When you pack it, you must tell the manufacturer that it is used for packaging.

2. When the product is compounded, the layering caused by the compounding master’s technology is not enough

Composite aluminum foil bags are generally composed of two or more layers of materials. In the composite process, these materials need to be carried out through a special process. In the composite process, the use of glue will more or less affect the layering of the bag.

3. Insufficient curing or too low or too short temperature causes delamination

After the composite aluminum foil bag is composited, it needs to be baked in an environment with a constant temperature of 50 degrees, and the time needs to reach 48 hours. This purpose is also to put glue and water to dry and grill. However, in order to save time, some manufacturers will take out the bags in advance and cut them to make them, causing delamination. This is why it takes 7-15 working days during the packaging manufacturing process.

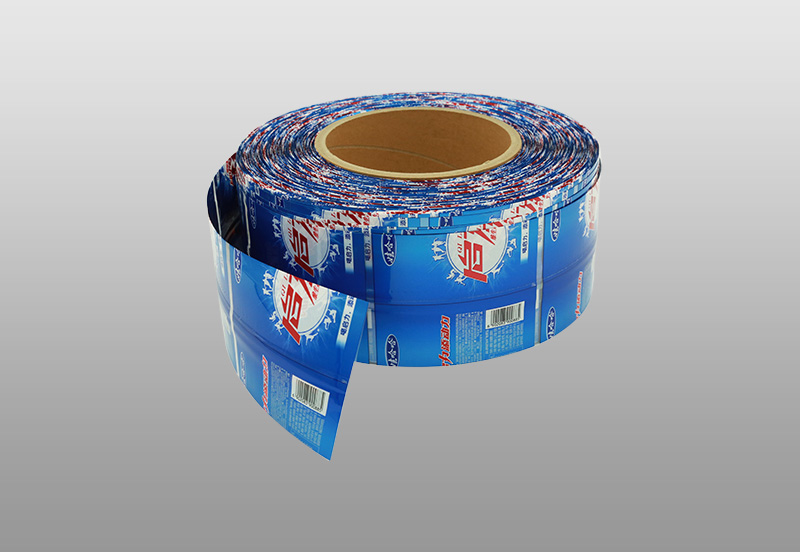

4. The influence of aluminum foil bag ink

First of all, due to the non-volatile active solvent in the ink, the resin or additives in the ink consume a part of the curing agent, which makes the main agent of the adhesive match the curing agent and the proportion of imbalance leads to heat seal delamination. Second, the ink layer itself has poor heat resistance, and the ink layer is destroyed during heat sealing, resulting in heat sealing separation. When using heat-resistant polyester amine, heat-sealing delamination may occur when inks or ammoniated polypropylene inks are used in high-temperature heat-sealing situations.

English

English Español

Español русский

русский 简体中文

简体中文