1.Polyester

Has excellent transparency, heat resistance and abrasion resistance. The film has two thicknesses of 12 microns and 25 microns, and printing is done on polyester. It can be used as a cover material for cooking bags or pan-shaped containers. PET

2. Nylon

It is indispensable as a base material for packaging materials for soft cans. The stretch film first used EVA as the self-adhesive material, but its cost was high and it had a taste. Later, PIB and VLDPE were used as self-adhesive materials. The base material is now mainly LLDPE, including C4, C6, C8 and metallocene PE ( MPE). There are two kinds of biaxial stretching and unstretched. Biaxially oriented nylon 6 film not only has excellent heat resistance and cold resistance, but also has good tear strength and pinhole resistance. Therefore, it can be used in combination with other raw materials. In addition, in order to prevent crimping and increase strength, some nylon 6-6 film is also used, but the price is higher than that of nylon 6.

3. Polyvinylidene chloride

As a single-layer film, it can also be used in soft cans. It can be used as a packaging material for ham and sausage. It has excellent sealing properties, binding properties, heat shrinkability, and gas barrier properties. Polyvinylidene chloride can also be used as a coating for nylon, polyester and other membrane materials. In addition, it is also used as a composite substrate for retort pouches and used on high-barrier polyvinylidene chloride films for high-temperature, high-pressure sterilization. PVDC

4. High-density polyethylene

Special high-density polyethylene for soft cans is commercially available in Japan. Although this kind of film has poor gas barrier properties, it can be used as a sealing layer due to its excellent tensile strength, elongation, tear strength, and good sealing adaptability. However, high-density polyethylene has several characteristics in terms of heat resistance, and its heat-resistant temperature is 120°C. HDPE

5. Polypropylene

It has good transparency, oil resistance, and heat resistance better than special polyethylene, so it can be used as a sealing layer for cooking bags and cooking containers. The sealing layer of soft can packaging materials mostly uses unstretched polypropylene film or sheet.

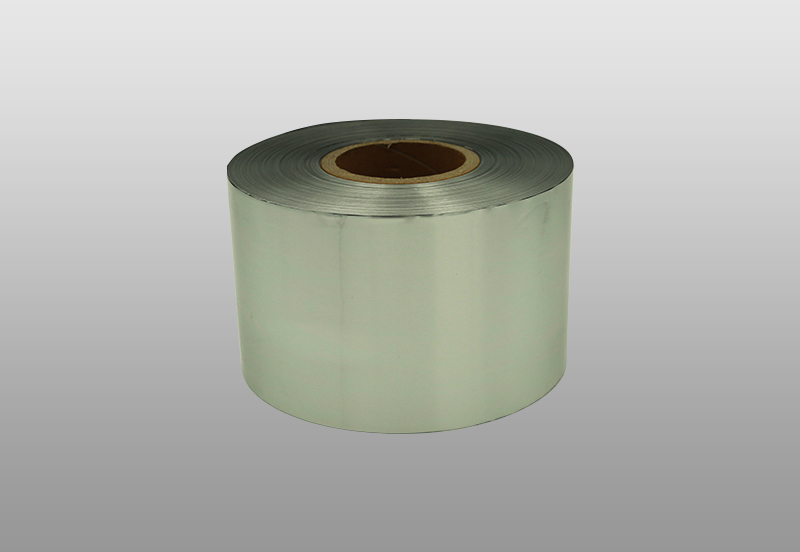

6. Aluminum foil

Aluminum foil is made of electrolytic aluminum with a purity of more than 99% and is made by rolling. When used as a packaging material, aluminum foil is the metal substrate in the packaging material. The thickness of the aluminum foil used in the cooking bag is 7-15 microns, and the thickness of the aluminum foil used in the cooking container is 50-130 microns. Because aluminum foil is non-toxic, tasteless, has excellent light-shielding properties, has extremely high moisture resistance, gas barrier properties and confidentiality, and can effectively protect the packaged materials, it is more suitable as a packaging material for fatty foods. However, due to the risk of pinholes after the aluminum foil is bent, it is necessary to use a plastic film as an outer layer to compound with it.

English

English Español

Español русский

русский 简体中文

简体中文