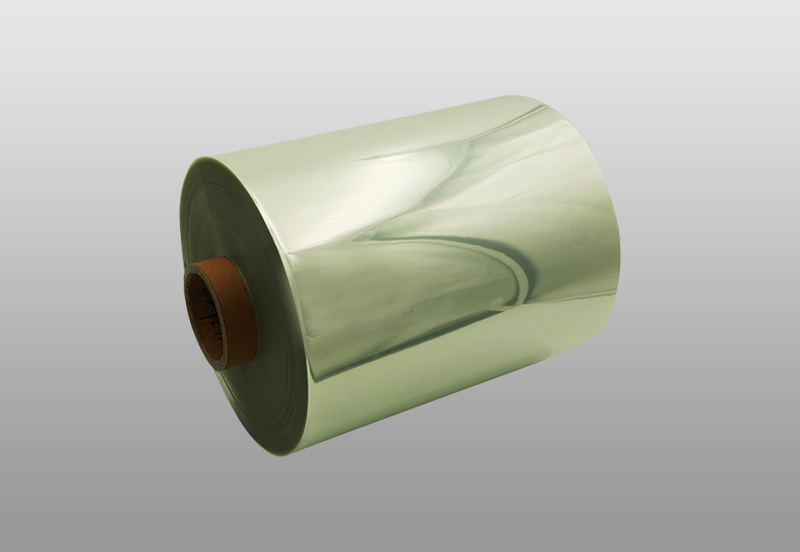

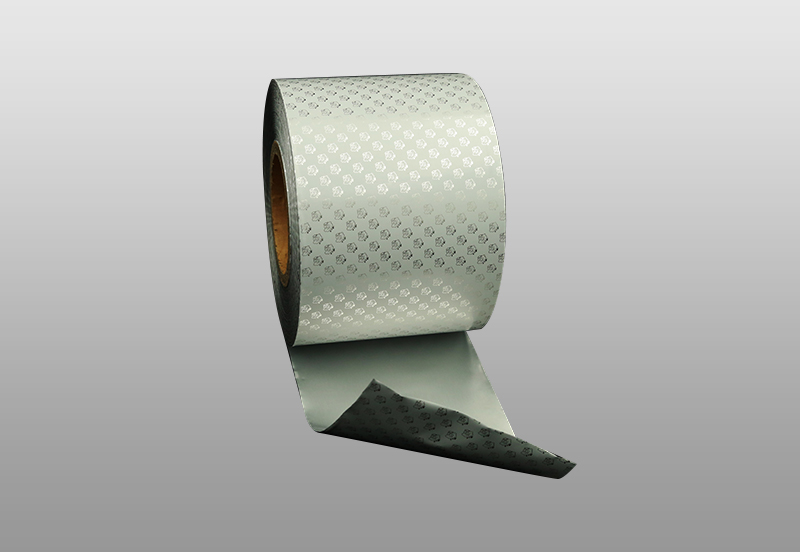

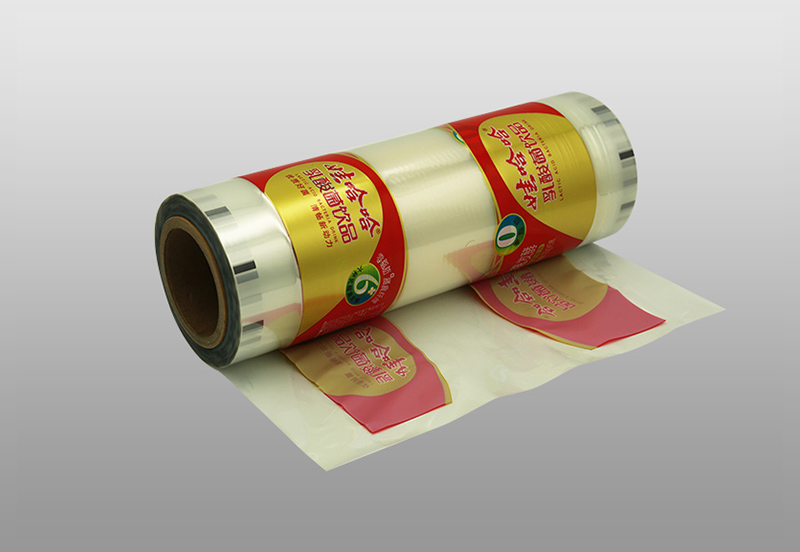

PE composite film is a multilayer structure that uses an adhesive system to combine substrates (OPP, OPA, OPET, aluminum, paper), etc. and polyethylene (PE) film (single layer or co-extrusion). It is two or two These materials are combined together through one or more composite processes to form a composite material with a certain function. What are the processing methods of pe composite film?

Processing methods are: extrusion compounding; wet compounding; solvent-based dry compounding; solvent-free dry compounding.

The extrusion compounding process is to use molten resin (polyethylene, polypropylene, EVA, ionic resin, etc.) as an adhesive or heat-sealing layer, coating it on various films for compounding, and then cooling and solidifying. In the process, if the second substrate is used, it is called extrusion compounding, and if the second substrate is not used, it is called extrusion coating.

The wet compounding process uses water-soluble glue, which is characterized by compounding first and then drying. At the moment when the two substrates are bonded together, the glue layer coated on the carrier substrate still contains a considerable amount of solvent. Therefore, the wet composite process is usually used for composite processing between paper and other substrates, and is widely used in paper/aluminum two-layer composite products for tobacco packaging and candy.

The solvent-based dry composite process and the solvent-free dry composite process have something in common: the moment the two substrates are bonded together, there is no solvent or diluent in the adhesive layer coated on the carrier substrate. Therefore, these two processes are collectively referred to as dry composite processes.

But there is a difference between the two: the adhesive or glue used by the former contains solvent, while the adhesive or glue used by the latter does not contain solvent. Therefore, the drying box is an essential part of the solvent-based dry laminating machine, but there is no drying box on the solvent-free dry laminating machine.

English

English Español

Español русский

русский 简体中文

简体中文