The quality of food packaging bags in the flexible packaging industry, especially the hygienic quality, is directly related to the safety of the packaged food. Therefore, it is necessary to ensure that the raw materials and additives used meet the quality requirements of the management system.

It is necessary to improve the industry and national standards of packaging film bags and strictly implement them, strengthen inspection and supervision of food packaging, prevent unqualified food packaging from entering the market, and strengthen management to ensure the healthy development of the flexible packaging industry.

The inspection items of food packaging single film bags are mainly divided into the following categories:

The appearance should not have any defects such as bubbles, perforations, water lines, violent tendons, poor plasticization, and fish-eye stiff blocks that are obstructive to use.

The specification, width, length and thickness deviation should be within the specified range.

The physical and mechanical properties include tensile strength and elongation at break, which reflect the ability of the product to be stretched during use. If this item is unqualified, the food packaging bag is prone to cracking and damage during use.

1. Hygienic performance

Including evaporation residue (acetic acid, ethanol, n-hexane), potassium permanganate consumption, heavy metals, decolorization test. Evaporation residue reflects the possibility that residues and heavy metals will precipitate when food packaging bags encounter vinegar, wine, oil and other liquids during use. Residues and heavy metals will have adverse effects on human health. In addition, residues will directly affect the color and aroma of food. Food quality such as, flavor.

2.Degradation performance

According to the different types of product degradation, it can be divided into photodegradable, biodegradable, and environmentally degradable. Degradation performance reflects the ability of the product to be accepted by the environment after use and disposal. If the degradation performance is good, the bag will break, differentiate and degrade by itself under the combined action of light and microorganisms, and eventually become debris, which is accepted by the natural environment; If the degradability is not good, it will not be accepted by the environment, thus forming "white pollution".

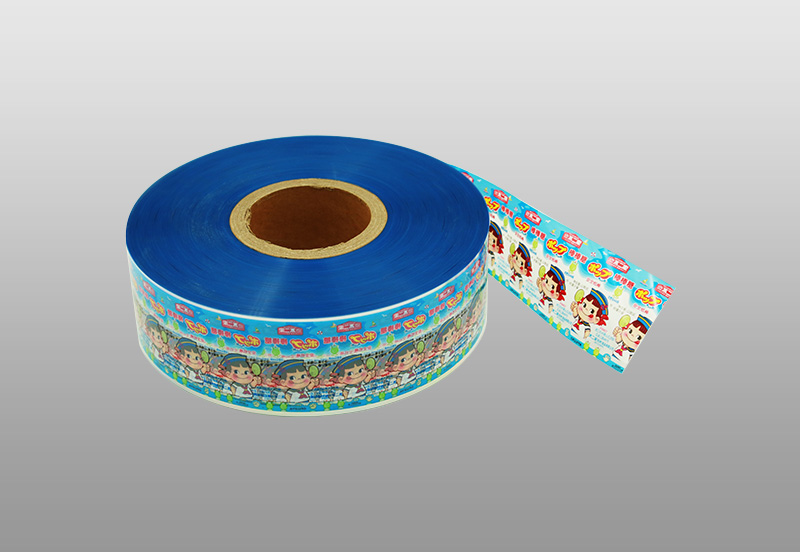

The inspection items of food packaging composite film bags are mainly divided into the following categories:

The appearance should be smooth, free from scratches, burns, bubbles, oil breaks and wrinkles, and the heat seal should be smooth and free of voids. The film shall not have cracks, pores and separation of the composite layer. There is no pollution such as impurities, foreign matter and oil stains.

The bagged soaking liquid shall not have peculiar smell, peculiar smell, turbidity and discoloration.

It needs to be pointed out that in addition to the above-mentioned corresponding sanitary standards for food packaging materials, my country has two laws and regulations: one is the "Food Sanitation Law of the People's Republic of China", and the other is the "Management Measures for Food Plastic Products and Raw Materials."

The Food Sanitation Law has more content than management measures, and it is a comprehensive law, while the latter is professional and only refers to plastic products and raw materials. The scope of management is limited to all kinds of plastic utensils, containers, production pipelines, and transportation that come into contact with food. Packaging materials made of tapes and plastics and the synthetic resins and additives used. The so-called plastic food utensils refer to plastic products such as spoons, spoons, and chopsticks that are in contact with food for a short period of time but need to be used repeatedly. The so-called container refers to plastic products such as barrels, bottles, basins, cups and so on that contain food. The so-called production pipeline refers to the pipeline through which materials in the food processing process, especially liquid food or beverages flow, and should also include storage and irrigation. The so-called conveyor belt refers to the carrier that transports the food raw materials to the processing equipment, and the packaging material refers to the single-piece and composite bottles, barrels, trays, roll films and bags. Bag film. All manufacturers of flexible food packaging and composite packaging materials should strictly implement this management method.

3. Physical and mechanical properties

Including tensile strength and elongation at break, it reflects the ability of the product to withstand stretching during use. If this item is unqualified, the food packaging bag will be prone to cracking and damage during use.

In addition, it also includes gas barrier properties such as gas permeability; oil resistance, heat resistance, cold resistance, and medium resistance; the sealing and peeling force of the bag, the pressure resistance and drop resistance of the bag, and other indicators. These indicators reflect the performance of food packaging bags. The reliability of the protection of the inner packaging.

The processing of plastic film bags must go through the process of heating, and plastics have the problems of cracking, oxidation, degradation, and deterioration when heated. Therefore, when processing plastic films or bags with resin, add antioxidants, Additives such as heat stabilizers. Some packaging film bags require anti-static, anti-condensation, and high slip due to the needs of packaging technology and machinery or contents, so additives such as anti-static agents, anti-fogging agents, lubricants, and opening agents are also added. All these auxiliaries must first be tested by GB15139 "Food Safety Toxicology Evaluation Procedures" to prove that they are non-toxic before they can be used, but there is also a limit on the amount of addition. Therefore, in the product, these low-molecular-weight substances that can be extracted, that is, evaporation residue, or things that can be oxidized and deteriorated, that is, the consumption of potassium permanganate, cannot exceed the prescribed amount, and if it exceeds it, it cannot be used. . Therefore, there must be corresponding hygienic standards for molded products. The purpose is to prevent misuse and abuse of additives, and to better ensure that materials directly packaged and in contact with food have a high degree of hygienic safety performance.

English

English Español

Español русский

русский 简体中文

简体中文