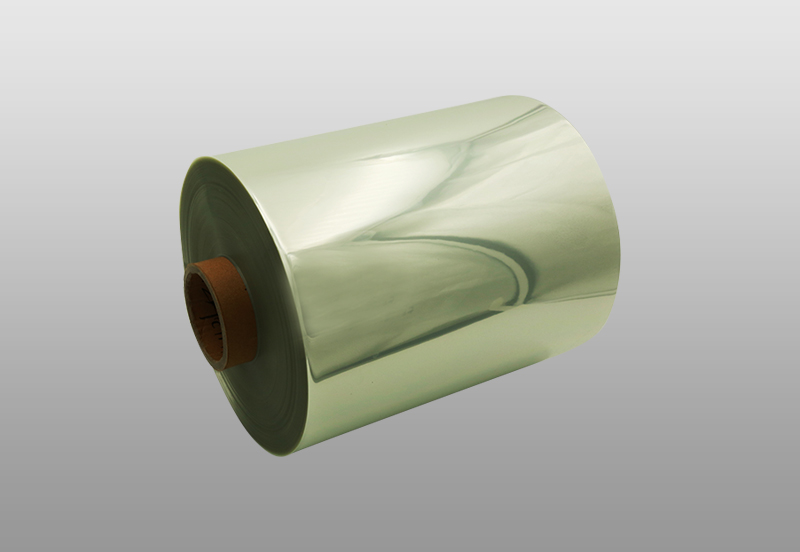

PETG (Polyethylene terephthalate), a transparent thermoplastic polymer, is an alternative to PVC (opolymer) and is used for a wide variety of electronics, plastics, coatings, dyes and binders. The high performance, low emission and chemical resistance make it a superior choice for many applications. PETG has many advantages over PVC. By the simple process of machine-directive rotation, PETG shrinks film from the top layer to the bottom without the use of heat underwriters. Moreover, PETG can be recycled easily and is environment-friendly.

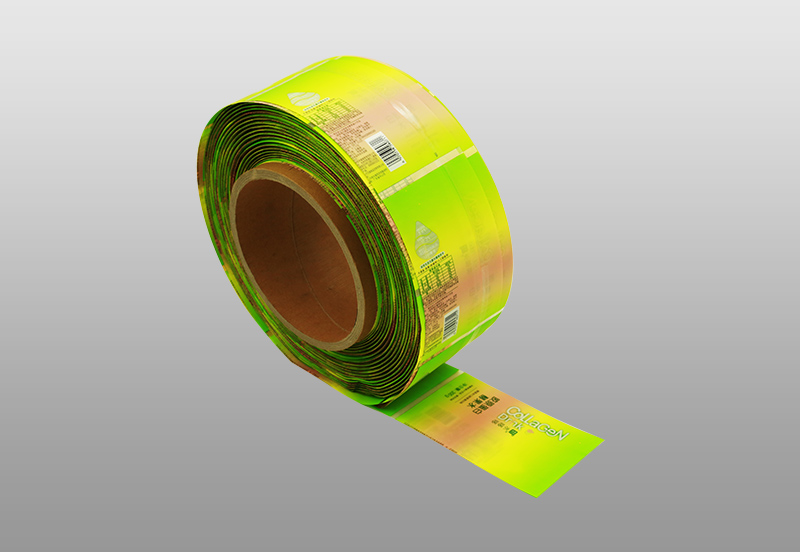

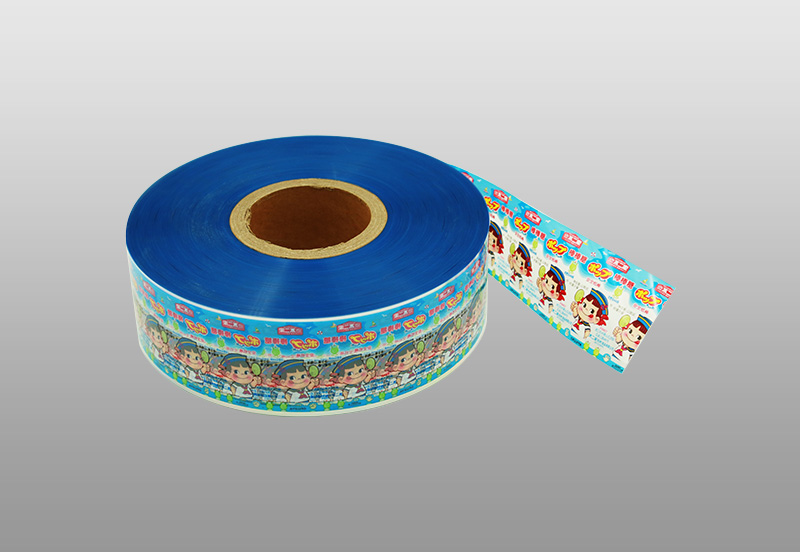

Since PETG is translucent, it can be printed with full color or with simple black & white imprints. It can be used to print labels on PETG shrink wrap or to apply decorations and decorative trims on containers and bottles. It can even be used to create or emboss brand names on bottles and containers. Some companies even print bar codes on PETG shrink wrap to improve container security.

In addition, PETG can be used to reduce the thickness of containers, especially soft containers like those used for liquids, or to increase the surface area. Companies that make and produce PETG use different methods to achieve the desired thickness, while maintaining the same properties as their PVC counterparts. When printing on the PETG shrinkable film, the required thickness can be determined and the required thickness can be applied by the company.

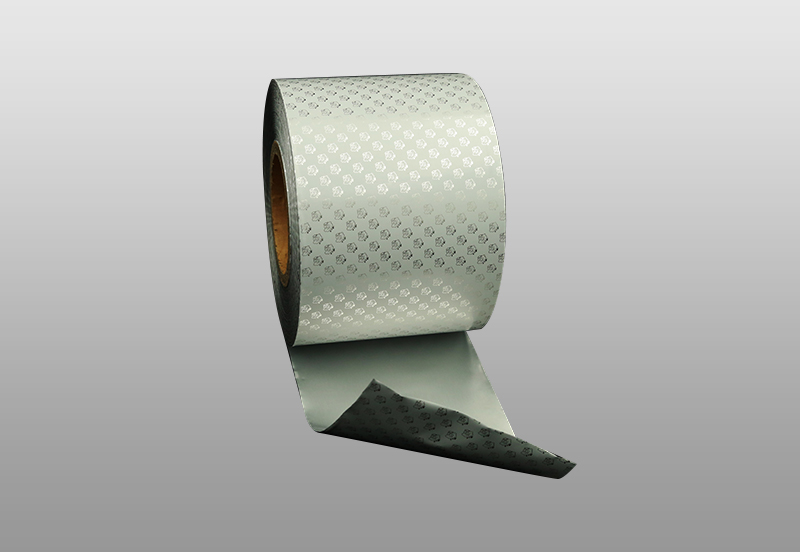

The most common method of printing on the PETG shrink wrap or to create a thicker, more detailed image is through the use of a hot ink pen. The thickness can be increased by allowing the ink to evaporate at room temperature, without heating the plastic sheet any further. Alternatively, the heat energy required to melt the PETG can also be controlled and measured, so that the exact amount of heat is applied to achieve the desired thickness.

The material can also be printed with a high or low melt-to-shrink ratio. High melt-to-shrink ratios are desirable when printing on the PETG shrink wrap because of the material's thermodynamic properties. This means that PETG does not change its shape during printing, unlike many other materials. However, PETG is difficult to manufacture with high melt-to-shrink ratios because the materials are usually thin, making it difficult to control. To overcome this problem, some PETG manufacturers use a combination of high and low melt-to-shrink ratios.

PETG can be used for all kinds of applications, including packaging, pharmaceuticals, personal protective equipment and medical devices. The material has no known health risks, although it is flammable under certain conditions. Because it does not react to changes in temperature or liquids, PETG is ideal for packaging in hot boxes. However, it is better to use standard packaging materials, such as polystyrene, foam and other rigid packaging, if PETG is to be used for personal protective equipment.

English

English Español

Español русский

русский 简体中文

简体中文