3. Co-extrusion compound method

The co-extrusion compounding method is a technology that uses multiple extruders to produce a multi-layered composite film through a multi-channel compounding head. This method has high requirements for equipment, especially the design of the machine head and process control. In recent years, with the maturity of mechanical processing and manufacturing technology, the co-extrusion composite method has developed rapidly, from the early 2-layer to the current 9-layer composite Films can be produced, and different materials can be selected according to functional needs.

The different plastics mentioned here can be different types of plastics, or the same type of plastics but different grades, or the same grades but different formulations of plastics. The cost of co-extrusion lamination is low, which can be reduced by 20%-30% compared with dry lamination, and no adhesive or anchor coating agent (AC agent) is used in the co-extrusion lamination process, so it is hygienic and has no environmental pollution problems. In terms of technology, co-extrusion compounding includes two methods: co-extrusion blown film and co-extrusion casting.

4. Evaporation composite method

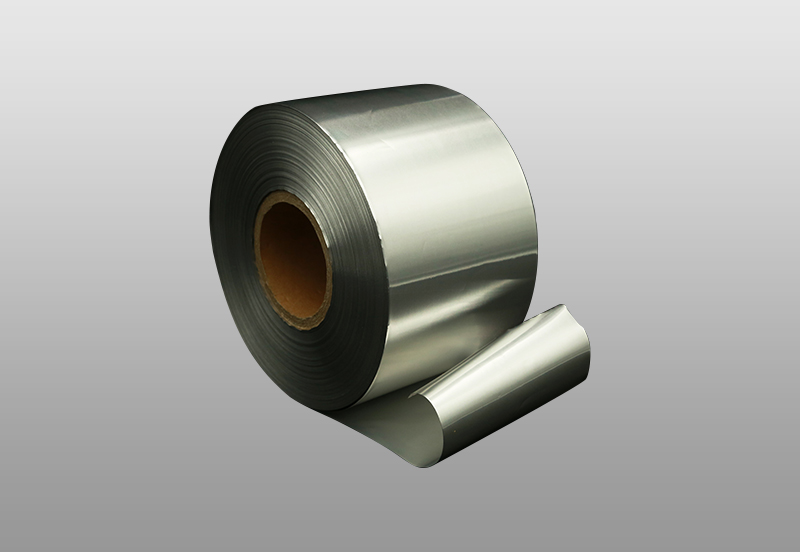

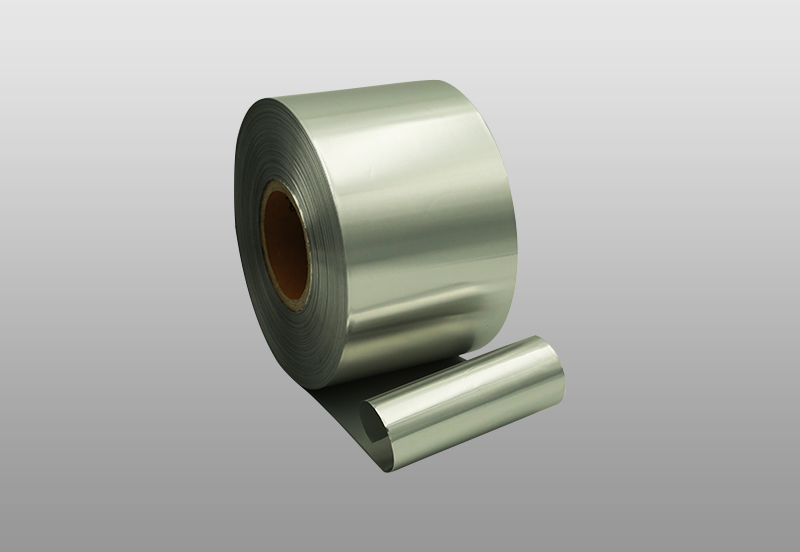

Evaporation composite method is a technology in which organic plastic film is used as the base material and inorganic material is composited. The dense inorganic layer can give the material barrier properties. Under high vacuum conditions, the aluminum wire is melted and evaporated at high temperature, and the aluminum vapor is precipitated and accumulated on the surface of the plastic film to form a barrier layer with a thickness of about 35-40 nm. The plastic film as the base material can be PE, P, PET, PA, PVC, etc., vacuum aluminized film has excellent barrier properties. In the case where transparent packaging is not required, aluminized film is the choice. Although the aluminized layer is very thin, its barrier performance reaches moisture permeability <0.1g /(m2?24h), oxygen permeability <0.1cm2/(m2?24h), its barrier properties are not affected by humidity.

English

English Español

Español русский

русский 简体中文

简体中文