There are four commonly used composite process methods for barrier plastic films: dry composite method, coating composite method, co-extrusion composite method and evaporation composite method.

1. Dry compound method

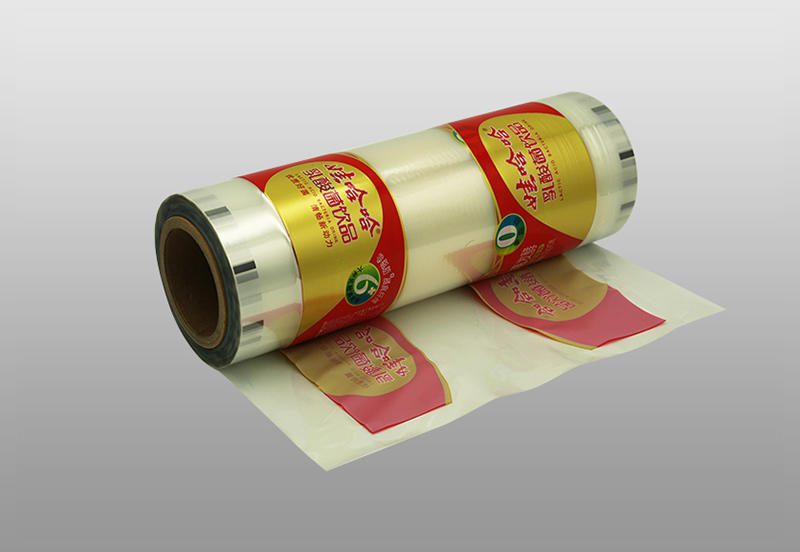

The dry lamination method uses various sheets or films as the base material, coats a layer of adhesive on the surface of the base material with a gravure roll, and after drying in a drying tunnel to make it sticky, it is then pressed and laminated on the lamination roll. It is a commonly used production method of composite film in China. The characteristics of dry lamination are that it has a wide range of adaptability and appropriate adhesives are selected. Any sheet or film can be composited, such as PE film, PP film, PET film, PA film. Film, etc., and the composite strength is high and the composite speed is fast. However, among these methods, the dry compounding cost is relatively high. In addition, since the amount of the adhesive is generally 2.5% and 5% (dry solid), there are problems of solvent residue and environmental pollution.

Dry lamination is suitable for a variety of composite film substrates and the lamination between film and aluminum foil and paper. It has a wide range of applications and has excellent resistance to chemical media erosion. For example, there are alkali, acid, spicy, oil and other ingredients in food, and cosmetics There are water, essence, emulsifier and other ingredients, and there are solvents, pesticides and other ingredients in chemicals, which are widely used in packaging with harsh content conditions.

2. Coating compound method

The process of coating composite method is relatively simple. For barrier resins that are difficult to be individually processed into films, such as PVA, PVDC, etc., coating composites can be used. At present, the more mature technology for the use of PVA and PVDC is the coating process. PVA is water-soluble. In actual use, a mixture of water and ethanol is used as a solvent to coat PE or P film with a thickness of 4-6gm PVA. Due to the poor water resistance of PVA, a cross-linking agent can be added to the PVA solution to improve its water resistance, and also improve the adhesion of PVA to PE and PP, so the primer coating can be omitted. For the convenience of bag making, coating The PE or PP film of PVA can be dry-compounded with other films to form a composite film coated with PVA/PE (or PP)/LDPE structure. This film has good barrier properties, and the vacuuming effect is better than PA/LDPE. , the cost is relatively low.

English

English 中文简体

中文简体 Español

Español русский

русский