There are many ways to prepare food antibacterial packaging films. One is to make an antibacterial agent into an antibacterial masterbatch, which is prepared by single-layer extrusion or salivation of an antibacterial agent or an antibacterial masterbatch and a resin. It can also be used as a surface layer and other layers to co-extrude to form an antibacterial composite film. Another is obtained by coating or evaporating an antibacterial agent on a resin film.

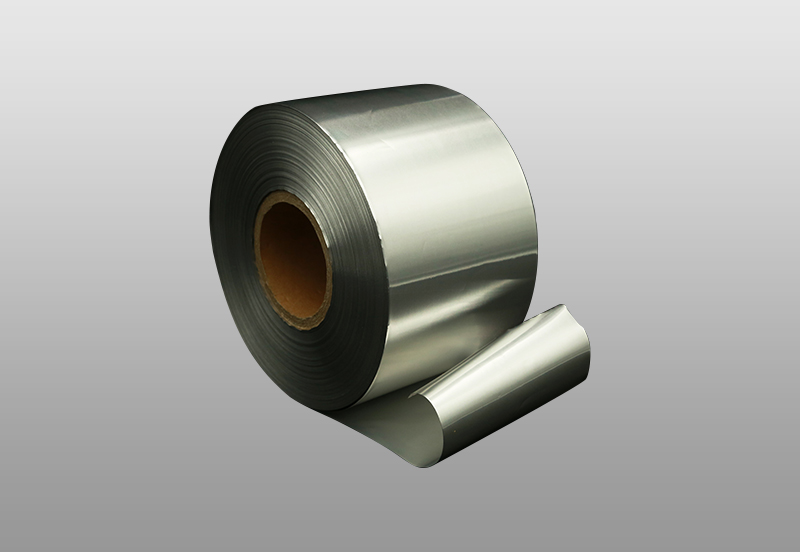

For the antibacterial film made from the antibacterial masterbatch, because the film itself is thin, the particle size of the antibacterial particles is required to be small, and the particle size distribution is relatively narrow, or the organic antibacterial agent that can be dissolved in the resin is used. Generally, the addition of antibacterial agent or antibacterial masterbatch has no obvious effect on the mechanical properties of the film, nor does it have an adverse effect on the printing performance of the film. But it has a certain impact on the barrier properties of some films, so when choosing antibacterial agents and antibacterial masterbatches, attention should be paid to the influence of the addition of antibacterial agents and antibacterial masterbatches on the performance of the film, and appropriate antibacterial agents are selected to ensure packaging performance Meet the requirements for use. Generally used packaging materials are LDPE, LLDPE, EVA, cellulose film, edible film and so on.

For the method of coating or evaporating antibacterial agents on the film, the barrier properties of different plastics are very different. If the substrate is not damaged during the coating and coating process, it can still affect the quality of the final product. The surface properties, performance polarity, surface roughness, the percentage of oxygen and nitrogen atoms on the surface of the plastic film will affect the bonding strength of the film and the antibacterial agent, thereby affecting the antibacterial performance. In addition, before coating or evaporating the antibacterial agent on the film, the surface of the film substrate should be pre-treated in advance to improve its surface energy and adhesion. Packaging film substrates used for coating or evaporation generally include PET, PA, PVC, BOPP, LDPE, etc.

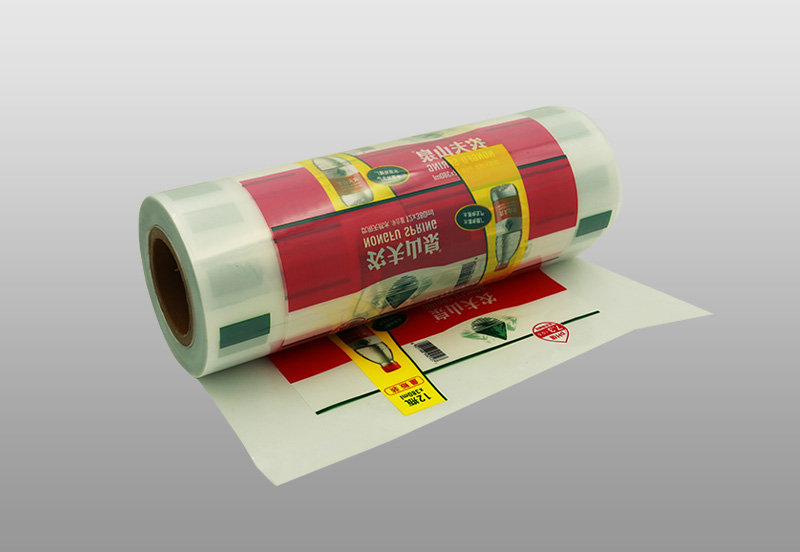

In addition to the mechanical properties, printing properties, display properties and other necessary properties of packaging materials that meet the requirements of commodity packaging itself, food antibacterial packaging films have high requirements for the hygienic properties of packaging materials used for food items in all countries around the world. my country's national standard GB-9687 stipulates the hygienic requirements for food packaging materials, requiring the materials to have normal color, no peculiar smell, no peculiar smell, and no foreign matter, and in addition to evaporation residue, potassium permanganate consumption, heavy metal content, decolorization experiments, etc. Meet the corresponding requirements. The US FDA has also made specific regulations on the composition of food packaging materials, additive specifications, conditions of use, dissolution requirements, requirements for chronic toxicity tests of the dissolution of food packaging materials, and requirements for subchronic toxicity tests.

A compound antibacterial agent used in food packaging. The organic antibacterial agent triazine antifungal agent and pyridine antibacterial agent are compounded by the organic antibacterial agent triazine antibacterial agent on the Japanese market. Its antibacterial effect is improved by 3— 4 times. The composite antibacterial agent of organic antibacterial agent and inorganic antibacterial agent developed by the National Engineering Research Center of Haier Chemical Engineering Plastics in China overcomes the problem of single function of KFHS series antibacterial agents. In addition, nano-TiO2 can be added to inorganic silver-based antibacterial agents in food packaging films to solve the problem of slow antibacterial effects of silver-based antibacterial agents.

English

English Español

Español русский

русский 简体中文

简体中文