Inexpensive, high quality, environmentally friendly, easy to use

Under the same weight, the actual packaging area of the ultra-thin stretch film is about 3 times that of the traditional stretch film on the market. Compared with the traditional stretch film, the cost saving is considerable. Moreover, our green stretch film is a high-strength pre-stretched single-sided sticky stretch film, which is quite convenient to use, saving labor and money. The outer layer of the packaged object is not easy to stick to dust, and it is clean and hygienic.

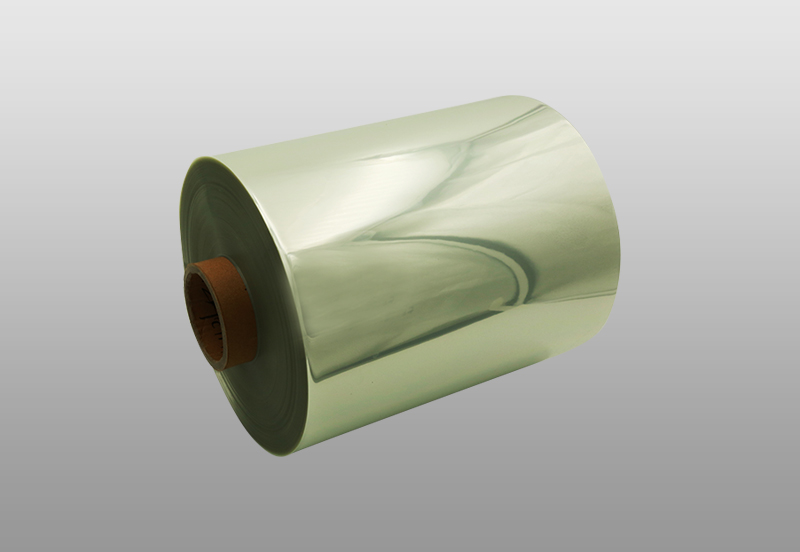

POF Shrink Film

POF has the characteristics of high surface gloss, good toughness, high tear strength, uniform heat shrinkage and suitable for automatic high-speed packaging. It is a replacement product of traditional PVC heat shrinkable film. POF is the meaning of heat shrinkable film. POF stands for multi-layer co-extruded polyolefin heat shrinkable film. It uses linear low density polyethylene as the middle layer (LLDPE) and copolymerized polypropylene (pp) as the inner and outer layers. It is plasticized and extruded out of the machine, and then processed by special processes such as die forming and film bubble inflation.

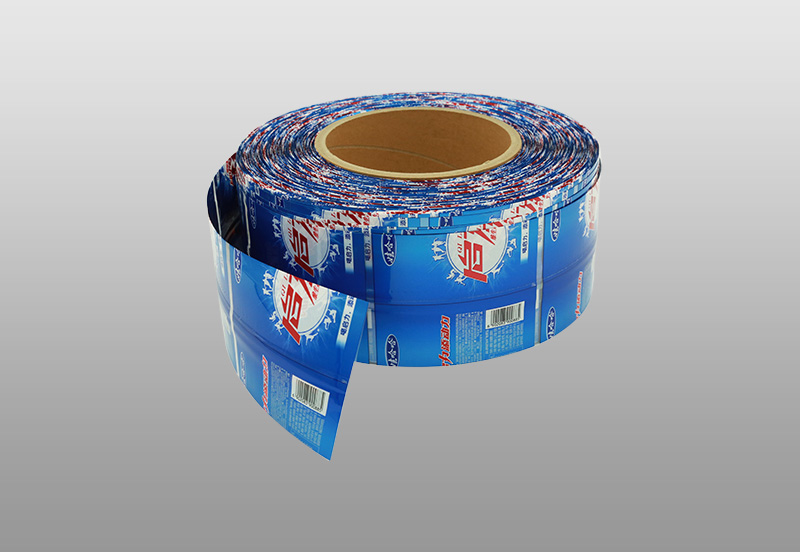

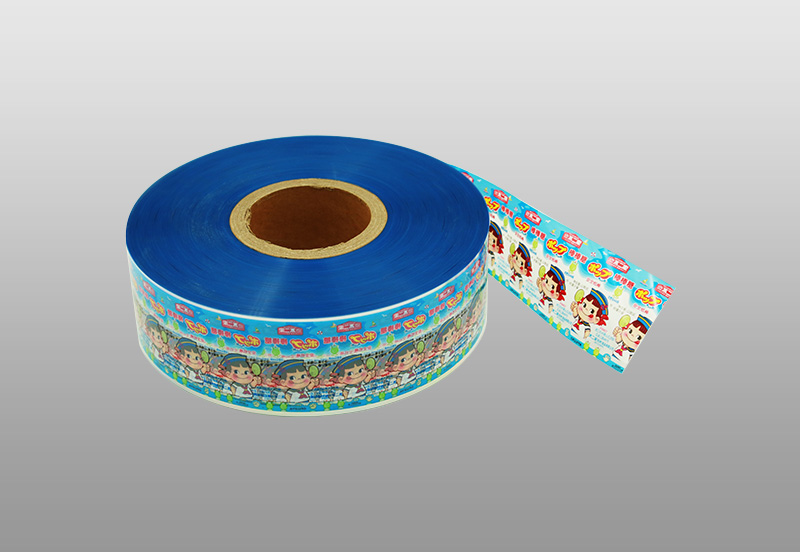

OPS shrink film

OPS (heat shrinkable film) is a new type of skin packaging material that meets environmental protection requirements. OPS heat shrinkable film has high strength, high rigidity, stable shape, and good gloss and transparency. It is easy to process, easy to color, has good printing performance, and has a very high printing resolution. For trademarks that constantly pursue exquisite printing, it is a complete improvement in material. Due to the high shrinkage rate and strength of OPS film, it can be closely attached to containers of various shapes, so it can not only print exquisite patterns, but also meet the use of various novel packaging containers with different shapes. This non-toxic, odorless, grease-resistant, food-hygienic film allows designers to use eye-catching colors to achieve 360° label designs, giving full play to creativity and imagination, so that beverages and other products can be used on labels. In-use patterns are more vivid, highlighting the image on the shelf, creating an unexpected container effect.

English

English Español

Español русский

русский 简体中文

简体中文