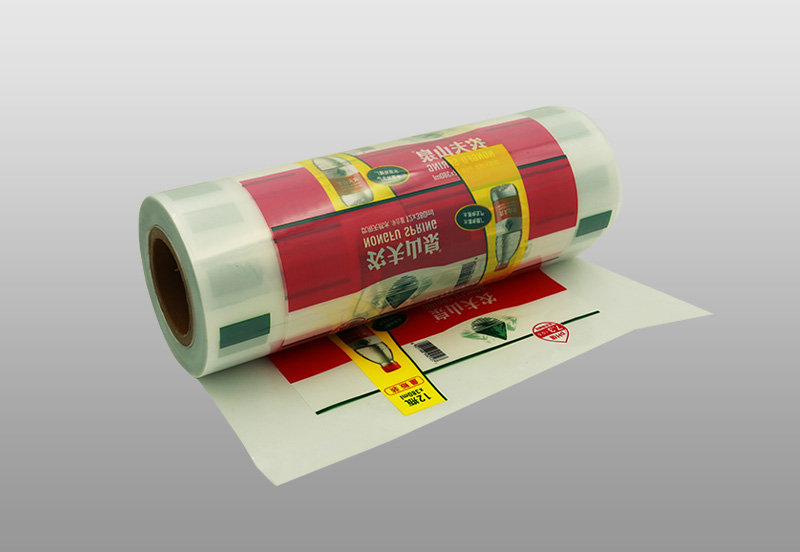

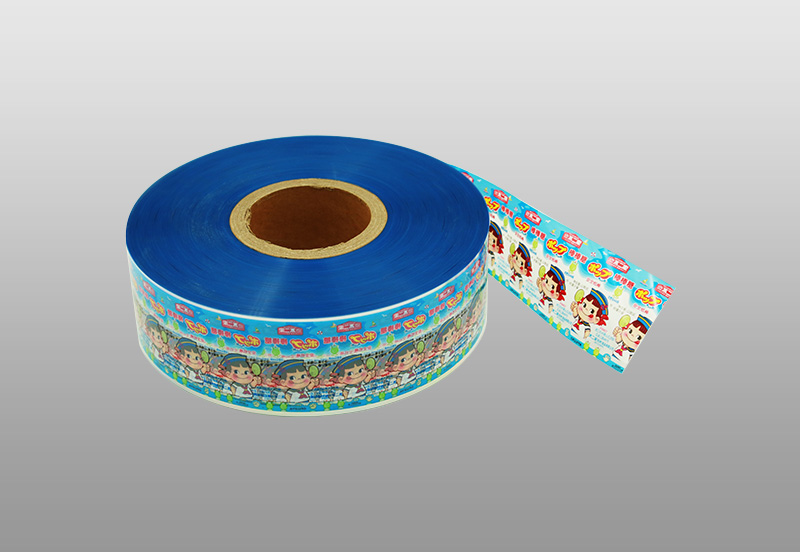

1. PVC (polyvinyl chloride): PVC shrink film has good transparency, high shrinkage, between 40% and 60%, and its cost is low, tensile strength is large, and temperature shrinkage range is large. The requirements are not high, and the main processing heat source is hot air, infrared rays or a combination of the two. However, the environmental protection of PVC shrink film is poor, PVC is difficult to recycle, and it produces poisonous gas when burned, which is not conducive to environmental protection. It has been banned in Europe and Japan. However, in my country, due to the low environmental requirements, PVC is still the most important material in the field of heat shrinkable labels.

2. PET film (polyester): PET film is an internationally recognized environmentally friendly heat shrinkable film material. Its technical indicators, physical properties, application range and use methods are close to PVC heat shrinkable film, and it is currently an advanced unidirectional shrinkable film. Its transverse shrinkage rate is 70%, longitudinal shrinkage rate is less than 3%, and it is non-toxic and pollution-free. It is the most ideal material to replace PVC.

3. PETG (modified polyester): Among various types of shrink film, PETG film is environmentally friendly, with a shrinkage rate of up to 78% and the shrinkage rate can be adjusted in advance. PETG shrink film occupies a larger market share, but its raw materials The cost is high, the shrinkage rate is too large, and it is limited in use.

4. OPS (Oriented Polystyrene): This is a widely used alternative to PVC film. Its shrinkage performance is good, up to 65%, which is also environmentally friendly. Compared with PVC shrink film, OPS shrink film has excellent environmental protection; compared with PETG shrink film, OPS shrink film is cheaper and more economical.

5. PE (Polyethylene): Polyethylene is recognized as a non-toxic material, especially suitable for product labeling in food, medicine, beverage and other industries. It can be made into a heat-shrinkable label with high transparency, good processing performance, high strength and environmental protection. However, due to its very stable non-polar properties, the printability is poor, and surface treatment is necessary. This limits its large-scale application to a certain extent.

6.0PP: OPP film has a low shrinkage rate, and it is mainly used in the field of shrink wrap labels. At the same time, it has good quality and low price, which is very competitive.

English

English Español

Español русский

русский 简体中文

简体中文