Several types of plastic heat-shrink sleeves can be used for packaging products. Some of these are polyolefin, Low-density polyethylene (LDPE), and PVC. Each type of plastic has unique characteristics, and experts are able to advise you on which material is best for your product. Read on to discover more about shrink sleeve materials. Listed below are some examples of their properties:

Polyolefin

The use of polyolefin heat shrink sleeve labels in PET bottles is the future of sustainable packaging. PET bottles can be recycled in the same way as those labeled with non-shrink films. However, this requires good label removal. To help make the recycling process easier, polyolefin heat shrink sleeve labels with TOPAS COC technology are available. These sleeves offer consistent seams and print treatment retention.

Polyolefin is a type of plastic polymer in the alkene family. It is used in a variety of industries and has numerous advantages over PVC shrink wrap. It is FDA-approved and is suitable for direct food contact. Its superior clarity and puncture resistance make it ideal for food-related applications. Furthermore, it is recyclable, reducing your environmental footprint. If you're wondering if polyolefin is right for you, check out some of these benefits.

Low-density polyethylene

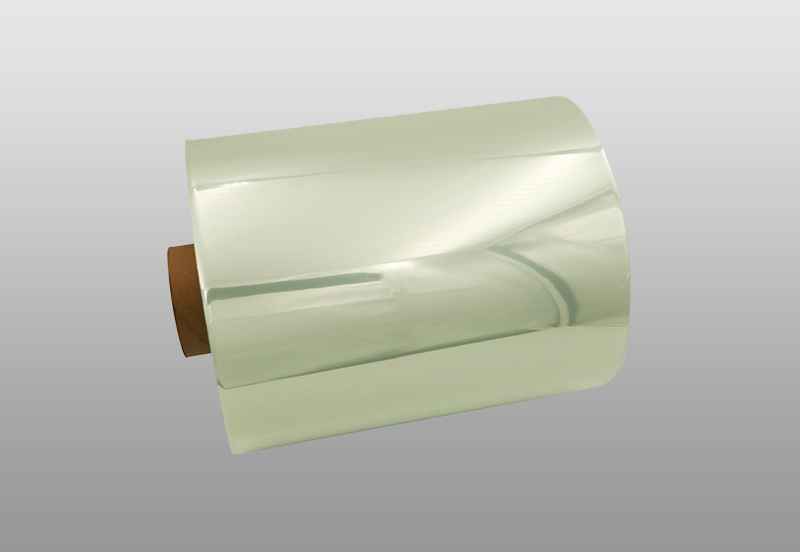

LDPE (Low-density polyethylene) shrink sleeves are one of the most common types of heat-shrink wrap used today. This material shrinks tightly around items and is excellent for pallet loads, nonstandard machines, and other non-standard packaging. The benefits of LDPE packaging are endless, from increased durability to improved appearance. Read on to find out why this material is the best choice for packaging your products.

The process of shrink wrapping varies, from flat to single wound films, depending on the density of the plastic. The film is cooled and sealed using a heat tunnel or shrink gun. The film can be as thin as a fingernail and is available in a variety of thicknesses, including micron and nanometer-sized shrink sleeve varieties. Low-density polyethylene film is the least expensive type of shrink wrap solution.

Polypropylene

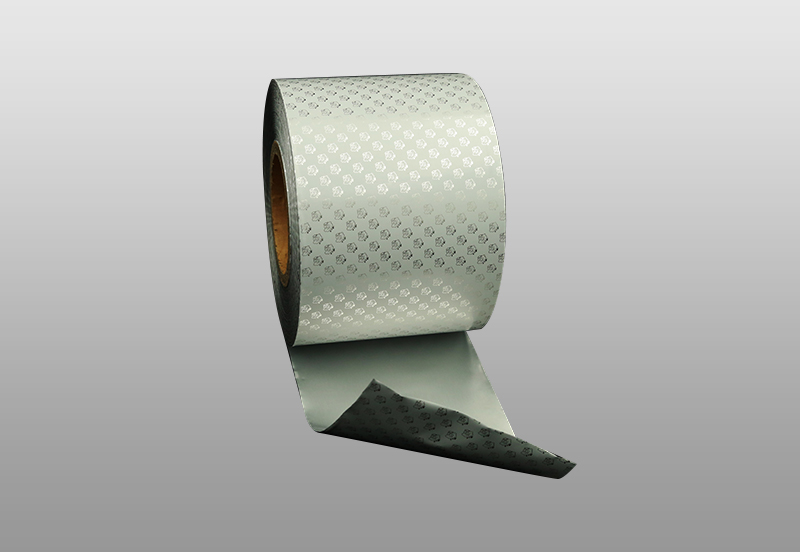

Heat shrinkable polypropylene (PP) heat shrink sleeve systems offer excellent long-term adhesion and mechanical protection. Designed with revolutionary hybrid material construction, they combine polypropylene (PP) based materials with mastic adhesives technology to give you industry-leading cycle times. Designed for fast installation and removal, PP shrink sleeves require St 3 surface preparation. In addition, they can be applied to a variety of substrates and are ideal for high-temperature applications.

Polypropylene heat shrink sleeves are available in various thicknesses and can be custom-made to fit a specific application. A standard 110 polypropylene heat shrinkable sleeve system can provide corrosion protection and lasts just as long as a 3-layer mill-applied coating. They can also be pre-cut to fit a specific pipe size. Aside from its high-quality adhesive properties, heat-shrinkable sleeves are compatible with PE, FBE, coal tar, and other coatings.

PVC

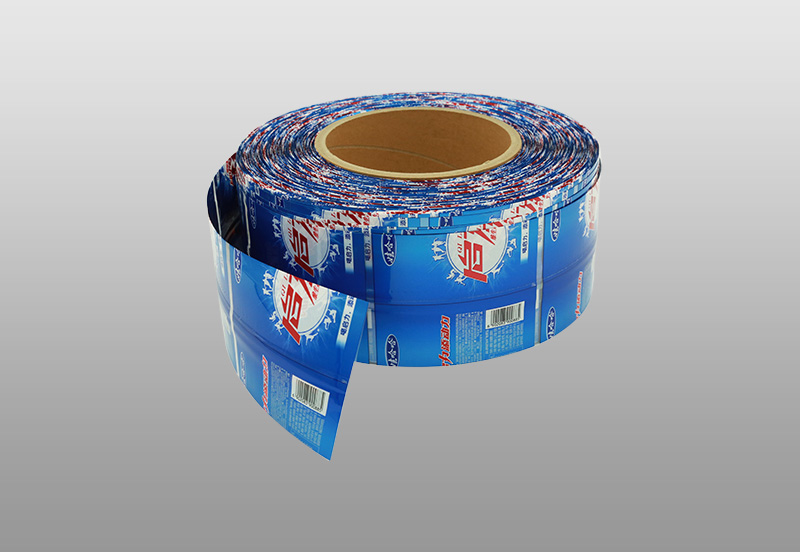

A shrink sleeve is a plastic film that is heat-shrunk around a container. The shrink sleeve is printed flat and is then seamed into a tube shape. The sleeve slides over the container and heats up to shrink it to the exact shape of the container. The shrink sleeve is a strong, waterproof barrier that can protect the product and keep it safe from moisture, dirt, and tamper-evident band.

This type of shrink sleeve is commonly made of Polyvinyl chloride (PVC), a high-density film that shrinks at a low temperature. It has several benefits, including good transparency, low shrinkage, and high strength. It also has a variety of shrink ratios and is highly durable. However, PVC shrink sleeves are not as environmentally friendly as other plastic shrink sleeves.

English

English Español

Español русский

русский 简体中文

简体中文