Vacuum packaging bags must use the principle of deoxygenation to effectively prevent food from spoiling and maintain its color, aroma, taste and nutritional value. It is widely used in the food industry. The safety of food vacuum packaging materials directly affects the safety of food. When performing vacuum packaging, choosing a good packaging material is the key to ensuring food safety. So, how to identify the safety of the material of the food vacuum packaging bag?

According to professionals, non-professionals may be indistinguishable, but they are toxic. Bags with a small amount of recycled materials used as food bags are harmful to the human body, so you should be cautious. Now introduce a few simple techniques to distinguish the material of food vacuum packaging bags.

1. Look at the color

The non-toxic polyethylene plastic is milky white and translucent. It has a paraffin waxy feel to the touch, and the texture is soft and bendable. It can float on the water surface when placed in water, and it will soften significantly in boiling water.

2. Smell

Non-toxic polyethylene plastic is easy to burn in fire, dripping wax when burning, swelling, and smells of petroleum. The flame is yellow, the lower end is blue, and a small amount of black smoke. It continues to burn after leaving the fire.

Poisonous polyvinyl chloride plastic is not as transparent as polyethylene, and it feels sticky to the touch. The texture is soft and elastic, and it becomes hard when cold. Sink in the water. It is not easy to burn, softens when burned, can be drawn, and has a pungent and spicy taste. The flame* is yellow, and the lower end is green with black smoke. Slowly extinguished after leaving the fire.

3. Look at the pull

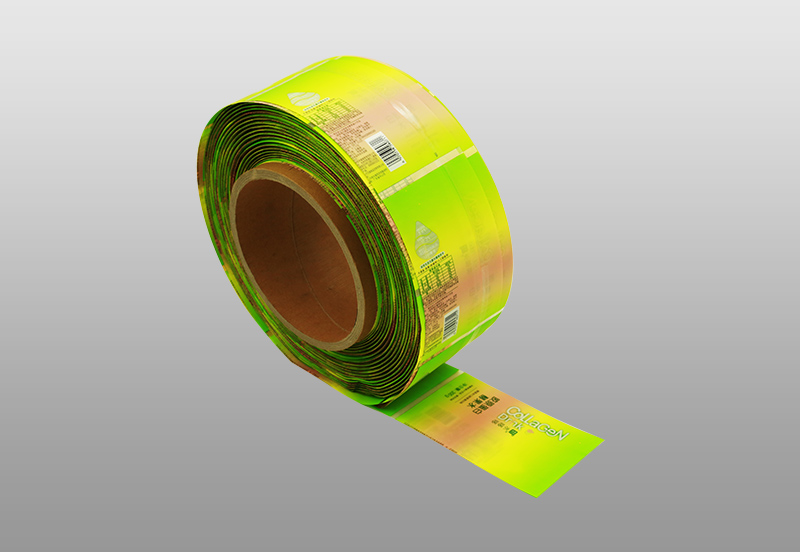

Vacuum packaging bags made of new materials have high strength and toughness, while vacuum packaging bags made of recycled materials have characteristics such as tensile strength and toughness.

1. Look at the color

The non-toxic polyethylene plastic is milky white and translucent. It has a paraffin waxy feel to the touch, and the texture is soft and bendable. It can float on the water surface when placed in water, and it will soften significantly in boiling water.

2. Smell

Non-toxic polyethylene plastic is easy to burn in fire, dripping wax when burning, swelling, and smells of petroleum. The flame is yellow, the lower end is blue, and a small amount of black smoke. It continues to burn after leaving the fire.

Poisonous polyvinyl chloride plastic is not as transparent as polyethylene, and it feels sticky to the touch. The texture is soft and elastic, and it becomes hard when cold. Sink in the water. It is not easy to burn, softens when burned, can be drawn, and has a pungent and spicy taste. The flame* is yellow, and the lower end is green with black smoke. Slowly extinguished after leaving the fire.

3. Look at the pull

Vacuum packaging bags made of new materials have high strength and toughness, while vacuum packaging bags made of recycled materials have characteristics such as tensile strength and toughness.

English

English Español

Español русский

русский 简体中文

简体中文